Corrugated Roof Roll Forming Machine consists of uncoiler and its base,infeed guides,fixd positiondriven forming stations,shearing device,hydraulic station,PLC control console and so on. Our company has hundreds of profile models for this series corrugated roof sheet machine,We can design different kinds of profile and fittings for machine,as per customers’ requirements.

1. Suitable material: Color steel sheet ,galvanized steel sheet, aluminium sheet

2. Width of material: 1200mm or as you required

3. Thickness of material: 0.3-0.8mm or as your needs

4. Working speed: 10-20m/min

5. Main motor power: 5.5kw with cycloidal reducer

6. Hydraulic station power: 5.5kw

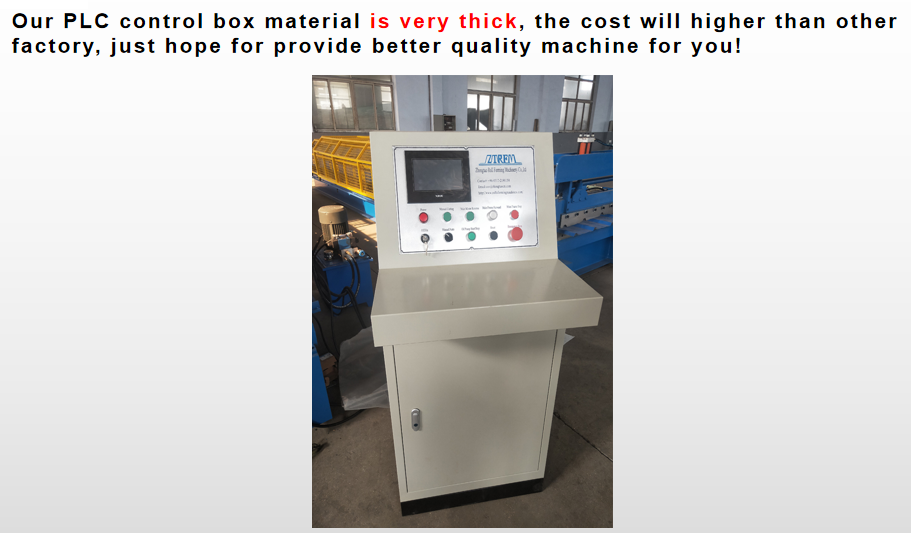

7. Electrical control system: PLC control system

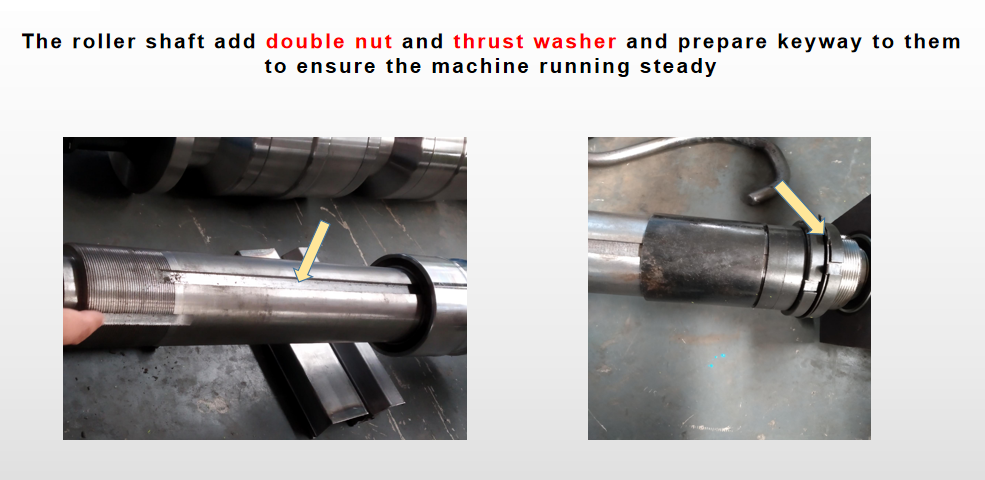

8. Shaft diameter: 80mm

9. Roller station: 12rows

10. Dimension: 7500x1500x1910mm

11. Weight: About 5 T

12. Voltage: 380V 3phase 50HZ or as the customer's requirements

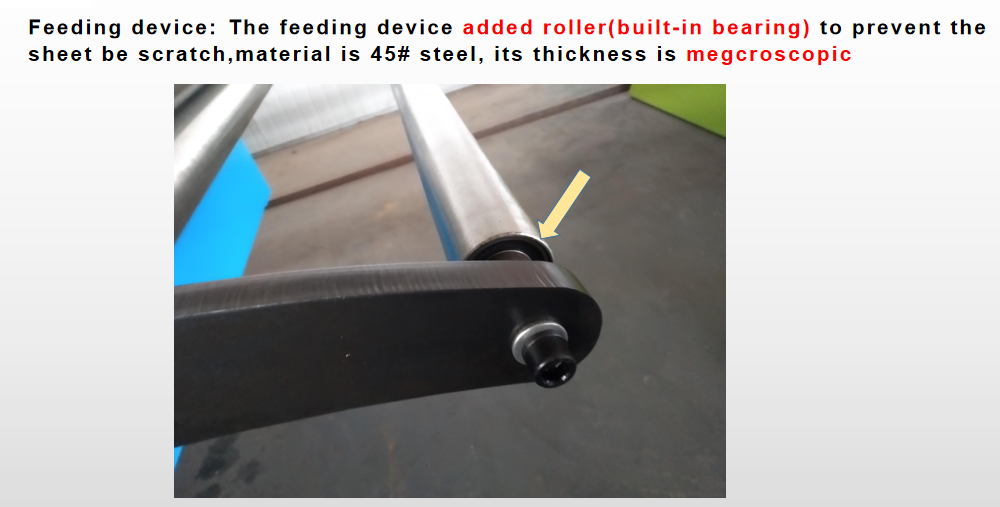

13. Material of roller: High grade 45# forged steel plated with hard chrome plating

14. Material of cutting: Cr12 mould steel with quenched treatment

15. Working time: Can be 24 hours

16. Workers: 1-2 only

Please Note: All the parameters can be designed as your requirement.

Let me show you how to operate Steel Bamboo Roofing Sheets Making Machine :

Decoiling→Feeding & Guiding→Roll Forming→ Cutting→Finished Products To Support Table